Not sure about your forge welding skills?

Get online access to a special step by step forge welding tutorial video by Magister Huber!

Short Summary

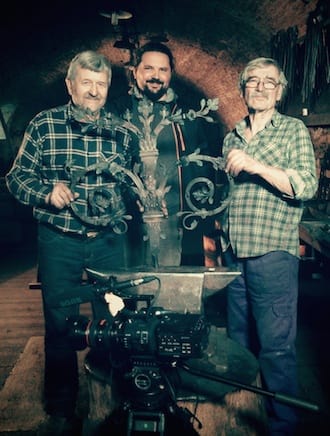

Some of our colleagues might have heard about our previous blacksmith video project, The Devil’s Blacksmith, which we shot with Walfrid Huber, Austrian sculptor and artist blacksmith. The film was made by Zoltán Takáts, Head of Hungarian Blacksmith Guild, artist blacksmith and Tamás Lehoczky, Hungarian filmmaker. We have got so much attention and positive feedback for this project so far that we decided to continue our journey to preserve and conserve the deeper levels of this unique heritage.

Why it’s important to us

Modern welding techniques are used exclusively in our field nowadays, and there’s so little chance to preserve traditional forge welding for future generations. Forge welding is one of the most stunning skills in our craft. You have to be familiar with this knowledge when working with historical styles or reconstruction projects, but it’s also a great technique when creating contemporary pieces.

The magnitude of what contributors will help us to achieve

By documenting this process we are not only preserving and conserving the theoretical and practical knowledge of forge welding, but also we would like to help our colleagues to be able to use this skill in everyday practice. You can be a professional or a hobbyist, there’s always a chance that you can deepen your knowledge and skills. Would you like to be part of this project? Then be part of Master Huber’s forge welding video tutorial! Help us reach our goal!

What We Need & What You Get

For completing this project we need to raise $6000. Preproduction and shooting costs are approx. $2500, postproduction costs are approx. $3500. We’ve worked more than 150 hours on our previous project, ‘The Devil’s Blacksmith, so far, so this one might be a bit longer process.

We are also planing to produce DVD versions of this video tutorial; some of you might choose it over the download link. Together we can make this project happen!

Magister Huber, our very good friend and colleague, is a living blacksmith legend for us. Some of you might already know his work from The Devil’s Blacksmith documentary. We’re truly honored that we have a chance to know and work with him. He has taught several blacksmith generations in the last decades and now – with your generous contribution – we have the opportunity to share his amazing talent all around the world with the help of these blacksmith videos.

What if we don’t reach our entire goal?

You do not need to worry if we cannot reach our $6000 goal in this campaign. This project is very flexible. The most important part is that he have already shot nearly the whole video with Master Huber. He’s turning 75 this year. There is sufficient time allocated to postproduction and we are flexible to reschedule several stages of the project depending on how the funds are starting to come in.

The Impact – The Devil’s Blacksmith story

With all your generous contributions we have managed to realize our previous blacksmith video project, ‘The Devil’s Blacksmith’. So far we have nearly 100 backers for that previous story of ours and we’ve collected approx. $5000 in the last few months.

For more information on ‘The Devil’s Blacksmith’ please follow us at our social profiles:

We are fortunate enough to be able to continue our journey in the topic of forge welding. Master Huber also has joined to the next phase of the project, and he’ll be leading this video tutorial, too.

Short excerpts of Devil’s Blacksmith

More info on The Devil’s Blacksmith documetary

Risks & Challenges

So once again: No risks. Anyone can contribute to the project in the campaign period (60 days), but you can also help us reach our goal after that.

Do not forget, sharing our project is also a great way of contribution.

Other Ways You Can Help

Some people just can’t contribute, but that doesn’t mean they can’t help.

Please share our project through the Indiegogo site. Feel free to use the Indiegogo share tools! You can also follow us and share our project at social media sites or you can subscribe to our newsletters and forward this campaign to your friends and colleagues. The more people get to know our goal the more chance we get for finishing our project successfully.

Thank you for your precious time. Together we can make this happen!

All the best,

The Devil’s Blacksmith/Blacksmithvideos Crew

Magister Walfrid Huber, Austrian artist, sculptor and blacksmith.

Zoltán Takáts, Head of Hungarian Blacksmith Guild, blacksmith and artist.

Tamás Lehoczky, Filmmaker

WALFRID HUBER, Austrian blacksmith, sculptor and artist was born in 1942. He attended and graduated from the Vocational School of Engineering in Salzburg in 1959. As an apprentice he learned the blacksmith trade at four different locksmith and blacksmith workshops and studios. After receiving his high school diploma in 1970, he continued his studies at the Vienna School of Arts and Crafts (now University of Applied Arts) as a sculptor, graduating in 1975. In this same year he opened his studio and workshop in Bad Pirawarth, where he continues to work to this day.

From 1980 to 1998 he began to teach at the University of Applied Arts. From 1993 he has also taught and is now the head of the blacksmith workshop at the training center of the Austrian Federal Office for the Care of Monuments in Mauerbach. He regularly holds courses on behalf of the Austrian Blacksmith and Locksmith Guild.

ZOLTÁN TAKÁTS, Hungarian blacksmith and artist was born in Pécs, Hungary in 1949. He graduated as a goldsmith from the Pécs High School of the Arts in 1968. Having worked as an apprentice for a blacksmith, he became an agricultural blacksmith in 1970. In 1972 he built his own studio and workshop in Pilisborosjenő, where he continues to work to this day.

In 1974 he received the title of Young Master of Folk Art and then the title of Master of Folk Art in 1980. Since 1986 he has been a member of the Hungarian Artists’ Association. He is a founding member, and since 1992 the guild master of the Hungarian Blacksmith Guild.

Since 2006 he has been a member of the Folk Art Evaluation Committee. As part of a commission from the National Institute of Vocational Education, the Chamber of Industry and the Ministry of Education he has written educational materials for the basic and advanced courses and their respective exams on the subject of ornamental blacksmithing. He has taken part in numerous solo and group exhibitions in Hungary and in several European cities since 1971. When not exhibiting alone, his wife, the goldsmith Ágnes Bartha, primarily joins him.

TAMAS LEHOCZKY, Filmmaker

The Devil’s Blacksmith short story:

The Notre-Dame Cathedral in Paris is one of the most remarkable masterpieces in the history of architecture. The portals of the main facade boast decorative wrought-iron hinges that represent extraordinary value in the world of art and in the blacksmith trade alike. These wonderfully crafted hinges were made at the end of the twelfth century, and their high artistic quality showcase a true master.

The blacksmith, who forged them, was called “Bicornett” (Two-Horned) by his contemporaries because the popular belief was that such things could only be created with the help of the Devil himself. Legend has it that Master Bicornett could finish the work on the side portals, but the one facing the altar in the central nave was never to be set up due to the Devil’s evil intentions.

The truth is that the portal disappeared during the French Revolution, and it was only replaced in the 1860’s thanks to the restoration works led by Viollet-le-Duc. They were fortunate enough to find an excellent blacksmith, Pierre Boulanger, who was not only able to recreate the hinges on par with the originals, but also improved the design with his precision and attention to detail. Since that time this knowledge has seemed to be lost forever and a great number of craftsmen have tried to get around the problem without success.

These hinges form a very complex pattern by plastically combining nature-inspired decorative elements such as leaves, flowers and animal heads. In addition, there are cover plates and bands applied to the crossing branches that need to be placed properly, which even skillful craftsmen find completely impossible. What seemed impossible to solve was how all these intricate pieces – which were all different in size and weight – could be set together with forge welding in such a way that they would not be damaged but would make one solid structure.

In forge welding the pieces of metal are heated to almost their melting point, then fitted and hammered together. This takes great practice and attention even in simpler structures. However, we’d have thought it to be impossible in a piece as complex and intricate as the hinges of the portal of the Notre-Dame. In today’s world, where forge welding has almost entirely been rendered obsolete by modern welding technology, it seemed impossible to crack the mystery of how the hinges of the Notre Dame were made. But there is someone who achieved the impossible.

Walfrid Huber, Austrian blacksmith and artist is an avid researcher of the style and technical history of the blacksmith tradition. As many other blacksmiths, he also faced the same agonizing question: how were the hinges of the Notre Dame made? However, after lots of brainstorming, countless hours of trial and error and a lucky visit to a museum it all paid off: he was able to solve the riddle!

At the Musée Cluny he found a piece, which was very similar in structure and construction to the hinges of the Notre Dame. When he held it in his hands and examined it from all sides he was finally able to see all the layers. With this knowledge he has been able to devise the sequence of steps that are necessary to create this masterpiece.

Indiegogo campaign (closed)

How to be The Devil’s Blacksmith – Teasers

#1

For more information please follow us at our social profiles.